Have you ever wondered how some cars seem to effortlessly leave others in the dust? The secret lies in the power of turbochargers. These remarkable devices are transforming the automotive landscape, delivering a thrilling boost in speed and performance that leaves naturally aspirated engines in the rearview mirror. But what exactly makes turbochargers so special, and how can they unlock your car’s full potential?

Key Takeaways

- Turbochargers can increase engine power by up to 40% compared to naturally aspirated engines.

- Turbo technology allows for smaller, more efficient engines to match the performance of larger ones.

- Turbochargers can help engines operate more efficiently at high altitudes where air is thinner.

- Turbocharging can decrease an engine’s specific fuel consumption by up to 14%, leading to improved fuel efficiency.

- A well-implemented turbocharger can add 75 to 150 horsepower to your engine.

The Power of Forced Induction

In the world of automotive performance, turbochargers have emerged as a game-changer, offering drivers the opportunity to unlock their engine’s true potential. Turbochargers employ the concept of forced induction, using the exhaust flow from the engine to drive a turbine. This turbine is then connected to a compressor, which draws in and compresses air. The compressed air, being denser, allows the engine to pack more air into each cylinder, enabling the addition of more fuel and resulting in a significant boost in power and efficiency.

How Turbochargers Work

The heart of a turbocharger’s operation lies in the interplay between the turbine and the compressor. As the engine’s exhaust gases flow through the turbine, it spins at incredibly high speeds, up to 150,000 rotations per minute (rpm) – about 30 times faster than the engine itself. This rapid spin of the turbine is then transferred to the compressor, which draws in and compresses the incoming air, delivering a 30- to 40-percent improvement in power compared to a naturally aspirated engine.

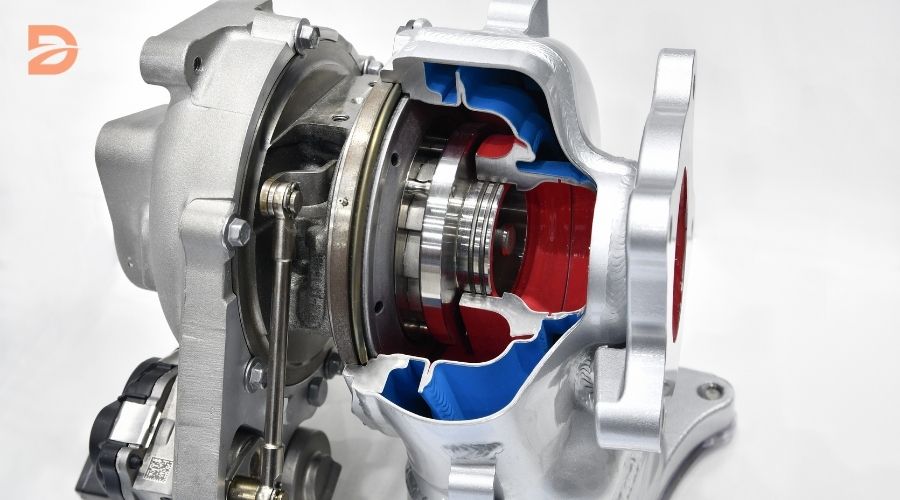

Turbocharger Components

Turbochargers are complex systems, consisting of several key components that work in harmony to deliver an impressive boost in power and efficiency. These components include:

- Turbine: The turbine is driven by the engine’s exhaust gases, converting the energy from the exhaust into rotational force.

- Compressor: The compressor is responsible for drawing in and compressing the incoming air, increasing its density, and enabling the engine to pack more air into each cylinder.

- Center Housing: The center housing serves as the structural core of the turbocharger, connecting the turbine and compressor components.

- Wastegate: The wastegate is a valve that allows excess exhaust gas to bypass the turbine, preventing the turbocharger from over-boosting and causing potential damage to the engine.

- Actuator: The actuator is responsible for controlling the wastegate, ensuring the turbocharger operates within its optimal range.

- Intercooler: The intercooler is a crucial component that further enhances the performance of a turbocharged engine by cooling the compressed air before it enters the engine, increasing its density and improving efficiency.

These intricate components work together seamlessly to transform the power of a turbocharged engine, delivering an exhilarating driving experience that takes performance to new heights.

Naturally Aspirated vs. Turbocharged Engines

When it comes to engine design, car enthusiasts often find themselves debating the merits of naturally aspirated (NA) engines versus turbocharged engines. Both have their unique advantages, catering to different driving preferences and performance needs.

Naturally aspirated engines rely solely on atmospheric pressure to draw in air for combustion, offering a pure, unaltered driving experience. These engines are prized for their reliability, linear power delivery, and the captivating sound that many car enthusiasts treasure. However, they may lack the power-enhancing boost provided by turbocharger technology.

On the other hand, turbocharged engines utilize forced induction to increase power and efficiency. By compressing the air entering the engine, turbos can significantly boost performance, allowing smaller engines to compete with the output of larger, naturally aspirated counterparts. Turbocharged engines have become increasingly popular in recent years, with around 65% of light vehicles in Europe being turbocharged by 2016, compared to only 40% in the United States.

The choice between naturally aspirated and turbocharged engines often comes down to personal preference and driving requirements. Naturally aspirated engines are prized for their purity and consistent power delivery, while turbocharged engines offer the thrill of enhanced performance and efficiency. Ultimately, both engine types have their unique advantages, catering to the diverse needs and preferences of modern car enthusiasts.

Water-Cooled Turbochargers: Enhancing Performance

Keeping Your Cool with Water-Cooled Turbos

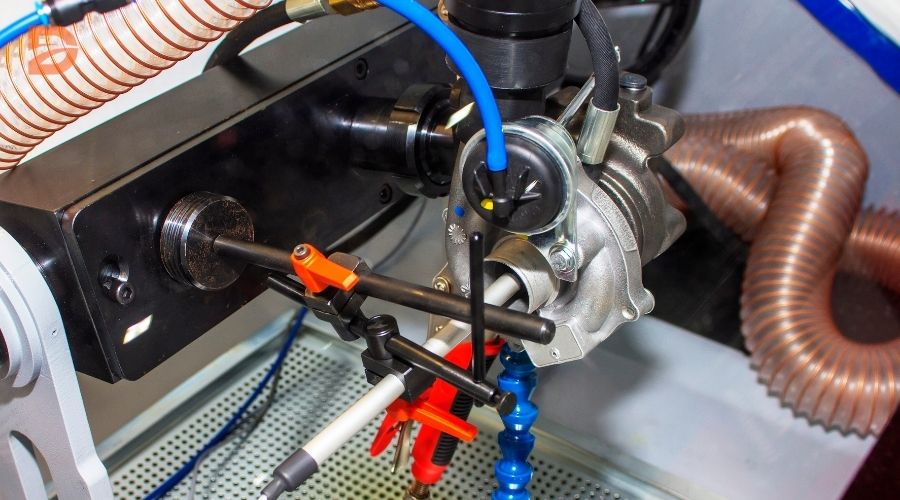

Turbochargers are the key to unlocking incredible power and efficiency from your engine, but they operate under immense heat and stress. Fortunately, water-cooled turbochargers offer a solution to this challenge, providing superior thermal management and enhancing overall performance.

Unlike traditional turbochargers that rely solely on oil for cooling and lubrication, water-cooled turbos use a dedicated cooling system to absorb the excess heat generated by the turbo’s operation. This water-based thermal management system helps control the turbocharger’s operating temperature, allowing it to run more efficiently and with greater durability.

The benefits of water-cooled turbochargers are particularly evident in high-performance applications, where the turbo is subjected to extreme conditions. By effectively dissipating heat, water-cooled turbos can deliver enhanced power, reliability, and longevity, making them a popular choice for enthusiasts and race car builders alike.

Proper setup and maintenance of the water-cooling system is crucial for ensuring the long-term health of a water-cooled turbocharger. Turbochargers that are not adequately cooled can suffer from premature bearing failure, oil seal degradation, and other issues that can lead to catastrophic damage. By prioritizing the turbo’s thermal management, you can unlock its full potential and enjoy the thrilling performance it has to offer.

Turbochargers, speed and performance: The Vband Connection

Turbochargers have evolved significantly over the years, and the Vband connection represents a cutting-edge advancement in this technology. A Vband turbo utilizes a specialized clamping system, known as a Vband clamp, to securely connect the turbocharger to the exhaust system. This robust and leak-free seal is crucial for maintaining the turbocharger’s efficiency and performance.

The Vband clamp is engineered to withstand the high temperatures and pressures present in the turbo system, ensuring a reliable and durable connection. This design also simplifies the installation and removal process of the turbocharger, allowing for quick and easy assembly and disassembly without the need for complex tools or procedures.

Vband turbos are highly sought after for their blend of performance, reliability, and convenience. The Vband connection is a testament to the constant evolution of turbo technology, as manufacturers strive to provide enthusiasts and performance-oriented drivers with the best possible solutions for unlocking their engine’s potential.

| Turbocharger Specification | Value |

|---|---|

| Turbine Housing Temperature Rating | Up to 1050°C |

| A/R (Area Over Radius) Measurement | Utilized to determine turbine performance |

| Twin Scroll Turbine Housing | Can improve boost response with twin scroll exhaust manifold |

| Garrett Performance Turbine Housing Inlet Connections | T25, T3, T4, T6, and V-Band |

The Vband connection’s popularity is on the rise due to its secure fit, flexibility, and ease of installation. With the various Vband inlet flange specifications offered by manufacturers like Garrett, enthusiasts can find the perfect solution to enhance the performance, reliability, and convenience of their turbocharged setup.

Externally Wastegated vs. Internally Wastegated Turbos

When it comes to turbocharger technology, the choice between externally wastegated and internally wastegated turbochargers is a crucial one. Each option offers distinct advantages, catering to different performance needs and driving preferences.

Externally Wastegated Turbochargers: Boost Control Mastery

Externally wastegated turbochargers feature a separate wastegate that is not built into the turbocharger housing. This design allows for more precise control over the boost pressure, making them an ideal choice for high-performance applications. With the ability to fine-tune the wastegate response, externally wastegated turbos can deliver a more aggressive and responsive boost feel, providing a significant advantage for enthusiasts seeking maximum power and control.

Internally Wastegated Turbochargers: Compact and Cost-Effective

In contrast, internally wastegated turbochargers have the wastegate built directly into the turbocharger housing. This integrated design simplifies the installation process and reduces the overall number of components, making them a more compact and cost-effective solution. While they may not offer the same level of boost pressure control as their external counterparts, internally wastegated turbos are well-suited for everyday driving applications where efficiency and versatility are prioritized.

| Feature | Externally Wastegated Turbochargers | Internally Wastegated Turbochargers |

|---|---|---|

| Boost Pressure Control | More precise control, allowing for an aggressive boost feel | Simpler boost control, suitable for everyday driving |

| Wastegate Valve Size | Larger, up to 60mm, for better flow and response | Smaller, 20-25mm, with limited flow capability |

| Packaging and Installation | Requires additional fabrication and modification | Compact design, easier to install |

| Cost | Higher due to required exhaust manifold modifications | More cost-effective for lower boost applications |

Understanding the differences between externally wastegated and internally wastegated turbochargers is crucial in making an informed decision that aligns with your performance goals and driving preferences. Whether you prioritize maximum power and control or seek a more practical and budget-friendly solution, the turbocharger technology you choose can make all the difference in unlocking your engine’s true potential.

Twin-Turbo Setups: Compounding the Power

The twin-turbo setup represents an exciting advancement in turbocharger technology, combining the benefits of a single turbocharger to deliver a potent boost in power and performance. This configuration utilizes two turbochargers working in tandem, either in a sequential or parallel arrangement, to compound the upsides of forced induction.

Sequential and Parallel Twin Turbo Systems

In a sequential twin turbo setup, the first turbocharger operates at lower engine speeds, providing increased torque and responsiveness from a standstill. As the revs climb, the second turbocharger kicks in, maintaining the power boost at higher engine speeds. This sequential approach can be more complex and expensive to engineer, but the results speak for themselves.

Alternatively, a parallel twin turbo setup involves two turbochargers of the same size, each feeding half of the engine’s cylinders. This parallel configuration offers impressive power delivery, with minimal turbo lag, by dividing the workload between the two turbos.

- Sequential twin turbo setups deliver enhanced low-end torque and high-end power.

- Parallel twin turbo setups provide a smoother, more linear power curve with reduced lag.

- Both twin-turbo configurations offer a significant boost in overall power and performance.

Regardless of the specific setup, twin-turbo systems represent a cutting-edge solution for unlocking the full potential of your engine. By compounding the power of forced induction, these advanced turbocharger arrangements deliver an unparalleled driving experience.

Conclusion: Unlock Your Engine’s Potential

Turbochargers have revolutionized the automotive industry, offering drivers a proven pathway to unlock their engine’s hidden potential. By harnessing the power of forced induction, turbochargers can significantly boost power output, delivering impressive gains in horsepower and acceleration. From water-cooled designs to advanced Vband connections, the continual evolution of turbo technology provides a versatile range of options to suit diverse driving needs and preferences.

Whether you’re seeking to enhance the performance of your daily driver or unleash the full potential of your high-performance vehicle, turbochargers offer a remarkable solution. By leveraging the benefits of turbocharging, such as increased efficiency, improved engine responsiveness, and greater overall vehicle performance, drivers can enjoy a thrilling driving experience.

As the demand for aftermarket upgrades and customization continues to grow, turbochargers have emerged as a popular choice among enthusiasts and performance-oriented drivers. By integrating advanced motor oils like Gravity® Drive Motor Oil, which are designed to withstand the rigors of turbocharged engines, drivers can further optimize their vehicle’s power and longevity. With a steadfast commitment to innovation and a deep understanding of the importance of proper maintenance, turbochargers have become an indispensable tool for those seeking to unlock their engine’s true potential.

FAQ

What are turbochargers and how do they work?

Turbochargers are turbine-driven devices that increase an internal combustion engine’s efficiency and power output by forcing extra air into the combustion chamber. They employ the concept of forced induction, using the exhaust flow to drive a turbine, which is connected to a compressor that draws in and compresses air, resulting in more power from each explosion.

What are the key components of a turbocharger?

The key components of a turbocharger include the turbine, compressor, center housing, wastegate, actuator, and intercooler, all working together to deliver an impressive boost in power and efficiency.

What is the difference between a naturally aspirated engine and a turbocharged engine?

A naturally aspirated engine relies solely on atmospheric pressure for air intake, while a turbocharged engine uses forced induction to increase power and efficiency, delivering a significant boost in performance.

What are the benefits of water-cooled turbochargers?

Water-cooled turbochargers use a cooling system to reduce the operating temperature of the turbo, enhancing its performance by allowing it to run more efficiently and extending its lifespan by reducing the risk of overheating and subsequent damage.

What is a Vband turbo and how does it differ from traditional turbochargers?

A Vband turbo represents an advanced form of turbo technology that uses a Vband connection to secure the turbocharger to the exhaust system, ensuring a robust and leak-free seal, which is critical for maintaining the turbocharger’s efficiency.

What are the differences between externally wastegated and internally wastegated turbochargers?

Externally wastegated turbochargers feature a separate wastegate not built into the turbo, allowing for better control over boost pressure and making them an ideal choice for high-performance applications. Internally wastegated turbochargers have the wastegate built directly into the turbocharger housing, simplifying installation and reducing the number of components.

What are the advantages of a twin-turbo setup?

A twin-turbo setup utilizes two turbochargers, either in a sequential or parallel setup, to compound the benefits of a single turbocharger. This can provide increased torque from a standing start, maintain power at higher engine revs, and offer impressive power boosts with minimal turbo lag.