In the quest to enhance fuel efficiency, reduce emissions, and improve overall vehicle performance, the automotive industry has turned its attention to the remarkable properties of carbon fiber. This high-strength, lightweight polymer composite has emerged as a game-changer, offering a potential solution to the challenges faced by automakers. But what exactly makes carbon fiber so revolutionary, and how is it poised to reshape the future of car design and performance?

Carbon fiber reinforced plastic (CFRP) boasts an unparalleled strength-to-weight ratio, with the ability to replace traditional steel and aluminum components with up to a 60% weight reduction. This dramatic decrease in vehicle mass has profound implications, from improved fuel economy and reduced carbon emissions to enhanced agility, handling, and acceleration. The automotive industry’s relentless pursuit of lightweighting has driven the widespread adoption of carbon fiber, as researchers and engineers harness its unique properties to push the boundaries of vehicle performance.

Key Takeaways

- Carbon fiber offers superior specific stiffness and strength compared to traditional metals, leading to enhanced vehicle performance.

- Replacing steel parts with carbon fiber reinforced plastic (CFRP) can result in a weight reduction of up to 60%, improving fuel efficiency and reducing emissions.

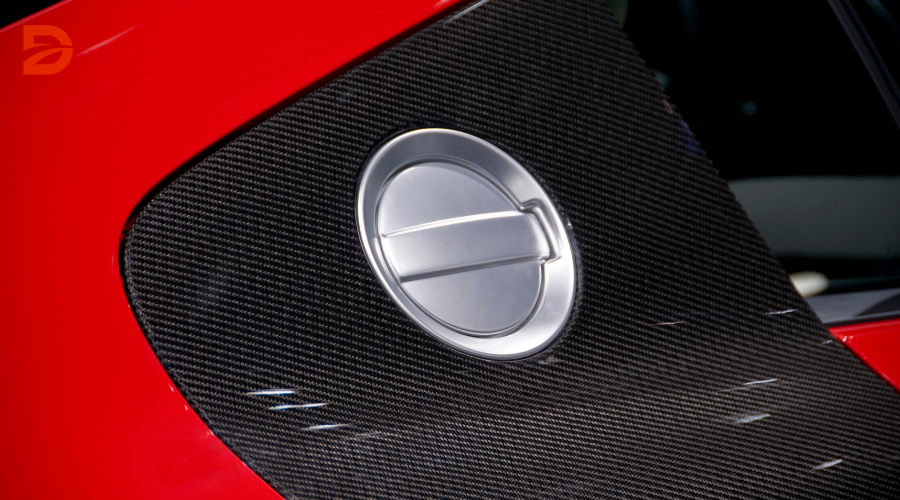

- The automotive industry is increasingly exploring carbon fiber applications in various vehicle components, such as chassis, body panels, engine cradles, and more.

- Carbon fiber’s high stiffness and strength contribute to better vehicle dynamics, handling, and acceleration.

- BMW’s investment in carbon fiber technology has challenged the notion that carbon fiber is limited to high-end sports cars, showcasing the potential for broader adoption in the automotive industry’s mass production processes.

Carbon Fiber’s Lightweight Strength Revolutionizing Automotive Design

The automotive industry has long sought materials that can enhance vehicle performance and efficiency without compromising safety. Carbon fiber composites, often referred to as CFRP (Carbon Fiber Reinforced Polymer), have emerged as a game-changing solution, revolutionizing the way cars are designed and engineered.

Outstanding Material Properties: Stiffness, Strength, and Lightweight

The exceptional properties of carbon fiber composites make them a standout choice for automotive applications. With their specific stiffness and specific strength surpassing that of traditional metals, CFRP offers unparalleled lightweight performance. Additionally, their superior fatigue properties ensure durability and reliability, making them ideal for critical components.

Critical Automotive Applications: Chassis, Bumpers, Engine Cradles

The transformative capabilities of carbon fiber composites have been leveraged in various automotive applications. In chassis design, CFRP’s stiffness and lightweight nature enhance vehicle dynamics and fuel efficiency, while its high strength-to-weight ratios improve impact performance and safety. CFRP has also been widely adopted in bumper construction and engine cradle integration, contributing to substantial weight reduction without compromising structural integrity or performance.

The integration of carbon fiber composites in automotive design has ushered in a new era of lightweight, high-performance vehicles that push the boundaries of efficiency and agility. As manufacturers continue to innovate and refine the use of this remarkable material, the future of automotive design promises to be even more exciting and transformative.

Overcoming Traditional Materials: The Limitations of Steel and Aluminum

As the automotive industry continues to evolve, the limitations of traditional materials like steel and aluminum have become increasingly apparent. These materials, while widely used for their affordability and availability, present significant challenges in the context of modern vehicle design and environmental sustainability.

Environmental Impact: Energy-Intensive Production and Fuel Consumption

The production of steel and aluminum is highly energy-intensive, contributing to substantial CO2 emissions. Additionally, the inherent weight of these materials leads to increased fuel consumption in vehicles, further exacerbating their environmental impact. This creates a pressing need for more sustainable alternatives that can reduce the carbon footprint of the automotive industry.

Cost Considerations: Long-Term Efficiency Gains with Carbon Fiber

While steel and aluminum may be relatively inexpensive compared to advanced composites like carbon fiber, their use in vehicles can lead to higher long-term costs due to the increased fuel consumption and environmental impact associated with their production. In contrast, the lightweight nature of carbon fiber offers significant performance limitations and crashworthiness advantages, ultimately contributing to improved energy absorption and reduced fuel consumption.

As the automotive industry continues to prioritize sustainability and efficiency, the transition towards lightweight materials like carbon fiber becomes increasingly crucial. By overcoming the limitations of traditional steel and aluminum, the industry can unlock new opportunities for enhanced fuel efficiency, reduced emissions, and improved overall vehicle performance.

Carbon fiber, lightweight materials: The Driving Force Behind Next-Gen Vehicles

As the automotive industry continues to evolve, carbon fiber lightweight design has emerged as a game-changing force, revolutionizing the way vehicles are engineered and manufactured. The inherent lightweight strength of carbon fiber has become the driving force behind the development of next-generation vehicles, offering a path towards enhanced fuel efficiency improvement and vehicle performance enhancement.

Enhanced Fuel Efficiency and Performance: Weight Reduction Benefits

The remarkable lightweight properties of carbon fiber-reinforced polymer (CFRP) have a profound impact on vehicle performance. By substituting traditional materials like steel and aluminum with CFRP, automakers can achieve significant weight reductions, which directly translate into improved fuel efficiency and enhanced overall vehicle performance. Studies have shown that a 10% reduction in vehicle weight can lead to a 6-7% increase in fuel economy, making CFRP a crucial contributor to the industry’s quest for greater sustainability.

Mass Production Potential: BMW’s Pioneering Work

The mass production of CFRP components has long been a challenge for the automotive industry, with carbon fiber’s high cost and complex manufacturing processes limiting its widespread adoption. However, BMW’s pioneering work in integrating carbon fiber into their vehicle designs has paved the way for a new era of accessibility. By establishing innovative production techniques and leveraging economies of scale, BMW has demonstrated the viability of BMW carbon fiber vehicles, setting the stage for a future where lightweight, high-performance cars are no longer confined to the realm of niche applications.

The Carbon Fiber Advantage in Motorsports

In the world of high-performance motorsports, carbon fiber has emerged as the material of choice, offering unparalleled advantages in terms of speed, agility, and safety. Its lightweight construction and exceptional strength make it a game-changer for race car design, revolutionizing the way vehicles are engineered and optimized for the track.

Lightweight Construction: Acceleration, Agility, and Handling

One of the primary benefits of carbon fiber in motorsports is its remarkable strength-to-weight ratio. Carbon fiber composite surpasses steel in strength and rigidity, providing a significant weight-saving advantage for race cars. This reduced weight directly translates to enhanced acceleration, as the vehicle requires less energy to reach high speeds. The lightweight nature of carbon fiber also contributes to improved handling and agility, with race cars exhibiting reduced body roll and increased stability even at high speeds.

Strength and Durability: Structural Integrity and Impact Resistance

In the high-speed, high-stakes world of motorsports, safety is of paramount importance. Carbon fiber’s unparalleled strength and durability make it an ideal choice for critical components such as chassis, roll cages, and suspension elements. The ability of carbon fiber to withstand high energy forces allows it to achieve higher levels of performance compared to steel parts, ensuring that the vehicle maintains its structural integrity even under the most demanding racing conditions. Moreover, carbon fiber’s inherent toughness disperses energy during collisions, minimizing damage and reducing the risk of injury to the driver, enhancing overall safety in motorsports.

The integration of carbon fiber in motorsports has revolutionized the way race cars are designed and engineered. From improved acceleration and handling to enhanced structural integrity and impact resistance, the material’s advantages have made it an essential component in the pursuit of high performance and safety on the track.

Conclusion

The automotive industry’s pursuit of enhanced fuel efficiency, reduced emissions, and improved performance has led to the revolutionary adoption of carbon fiber-reinforced plastic (CFRP). This advanced material’s exceptional strength-to-weight ratio, coupled with its durability and customizability, has transformed the design and engineering of modern vehicles.

From lightweight construction that boosts acceleration and handling to the material’s superior structural integrity and impact resistance, CFRP has emerged as a driving force behind the next generation of automobiles. As the industry continues to overcome cost and manufacturing challenges, the widespread integration of carbon fiber technology promises a future where vehicles are not only more efficient and high-performing but also more accessible to consumers.

The automotive industry’s embrace of CFRP marks a significant shift towards a more sustainable and innovative transportation landscape, redefining the boundaries of what is possible in the pursuit of automotive excellence. With its unparalleled properties and potential, carbon fiber-reinforced plastic is poised to revolutionize the way we design, engineer, and experience the automobiles of tomorrow.

FAQ

What makes carbon fiber a transformative material for the automotive industry?

Carbon fiber offers a unique combination of low weight, high strength, high rigidity, and resistance to fatigue and corrosion, making it a game-changing material for the automotive industry. Its exceptional specific stiffness and strength, coupled with superior fatigue properties, enable significant weight reduction, enhanced fuel efficiency, and improved vehicle performance and safety.

How does carbon fiber contribute to enhanced fuel efficiency and reduced emissions?

The lightweight nature of carbon fiber allows for significant weight reduction in vehicle components, directly translating into improved fuel economy and lower carbon emissions. Studies have shown that substituting traditional materials with carbon fiber can lead to weight reductions of up to 60%, resulting in substantial gains in fuel efficiency and environmental sustainability.

What are the key automotive applications of carbon fiber?

Carbon fiber has been widely adopted in critical automotive components such as chassis, bumpers, and engine cradles. The stiffness and lightweight properties of carbon fiber enhance vehicle dynamics, fuel efficiency, and impact performance, while its high strength-to-weight ratio helps maintain structural integrity and safety.

How does carbon fiber address the limitations of traditional automotive materials like steel and aluminum?

Steel and aluminum, the mainstays of automotive manufacturing, suffer from energy-intensive production processes that contribute to high CO2 emissions. Moreover, their heavy weight leads to increased fuel consumption, further exacerbating the environmental impact. In contrast, the lightweight nature of carbon fiber and its superior performance characteristics help overcome these limitations, offering a more sustainable and efficient solution for modern vehicle design.

How has the automotive industry embraced carbon fiber for mass production?

BMW’s pioneering work in integrating carbon fiber into their vehicle designs has challenged the notion that carbon fiber is solely reserved for high-end sports cars or niche applications. This breakthrough paves the way for the broader adoption of carbon fiber in the automotive industry, promising a future where vehicles are not only lighter and more efficient but also more accessible to consumers.

What are the key advantages of carbon fiber in motorsports?

In the world of motorsports, carbon fiber’s low weight is a significant advantage, directly contributing to enhanced speed, agility, and handling characteristics. The reduction in mass resulting from the use of carbon fiber components leads to improved acceleration, braking, and cornering performance. Additionally, carbon fiber’s remarkable strength and durability ensure the structural integrity of critical components, enhancing safety in high-speed racing environments.